How Heat Maps are Turning Data into Clear Floor Flatness Analysis

How Heat Maps are Turning Data into Clear Floor Flatness Analysis

In recent years, 3D scanning has revolutionized the field of surveying, collecting accurate, real-time spatial data within minutes. This information can be converted into advanced, highly detailed digital replicas, giving architects, engineers, and construction teams powerful tools to model and verify new construction designs. Beyond visualization, these 3D-rendered models deliver critical insights that support smarter decision-making throughout the project lifecycle. From initial planning and design to construction verification and post-completion analysis, this technology brings unparalleled clarity to key quality measures, such as floor flatness analysis, ensuring accuracy and efficiency at every stage.

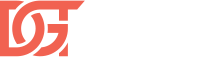

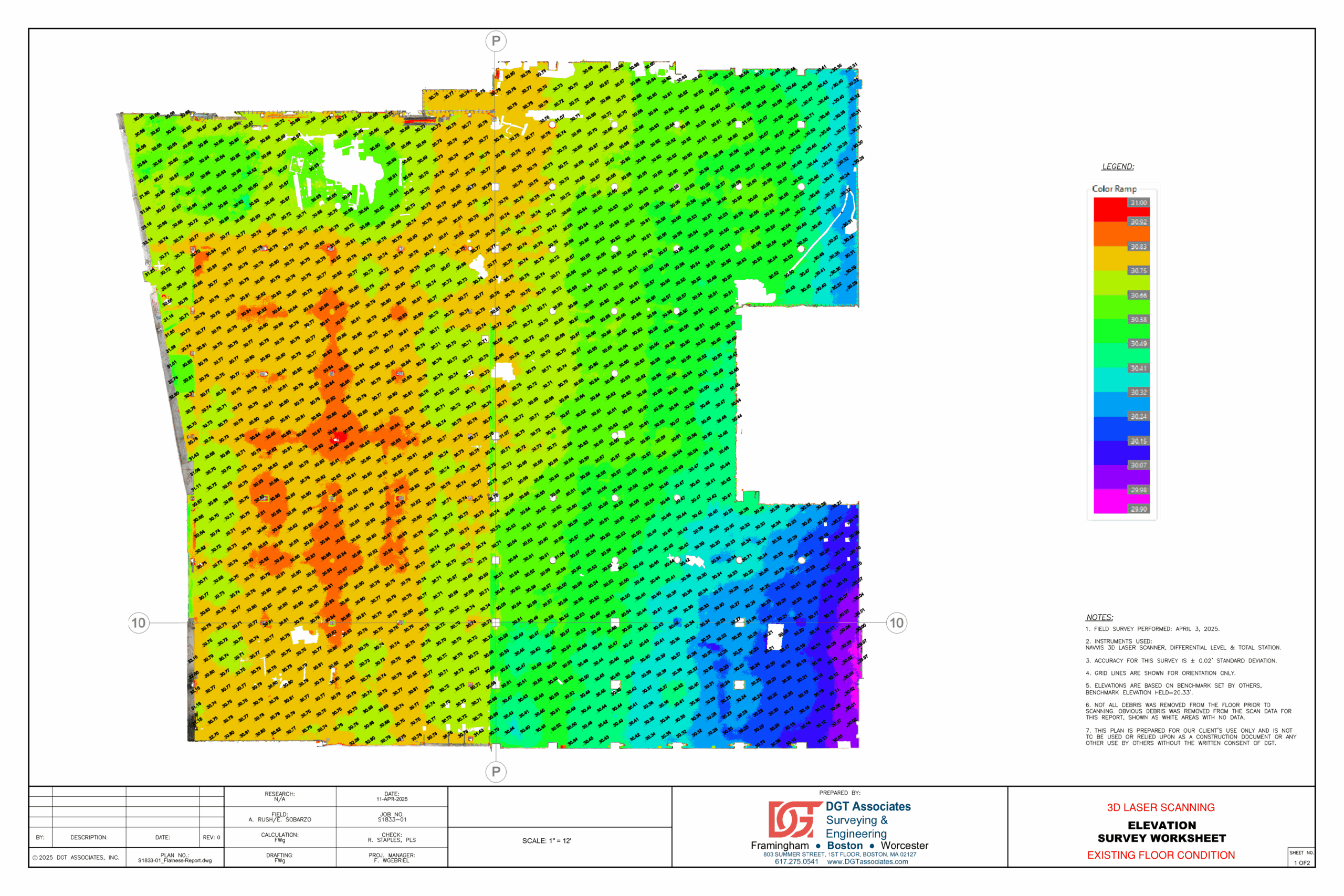

Whether in large-scale commercial builds, high-end residential projects, or specialized environments like laboratories and manufacturing facilities, floor flatness is a critical factor in maintaining structural integrity and ensuring the proper installation of finishes and equipment. Heat maps, generated from 3D scan data, take this a step further—turning raw floor flatness data into a color-coded visual that helps surveying professionals quickly identify high and low spots, allows decision-making teams to communicate findings earlier, and guides corrective action efficiently.

How 3D Scanning Powers Flatness Analysis

At the heart of modern flatness analysis is 3D laser scanning technology, which rapidly captures millions of surface data points. These measurements form a point cloud, a highly accurate digital model of the scanned area that records every rise, dip, and subtle variation in the floor surface. Once collected, the point cloud data is processed into detailed contour maps and heat maps—intuitive, color-coded visuals that track elevation changes across the floor surface.

Heat maps clearly identify low spots that require fill and high spots that require grinding or scarifying, giving project teams the insight they need to correct issues before they affect downstream work. The visual format makes it straightforward to communicate findings to stakeholders at all levels, regardless of their technical expertise. Beyond rapid identification, heat maps also enable data-driven planning, helping teams quantify the exact material and labor needs for cut-and-fill adjustments.

By transforming raw measurements into actionable insights, 3D scanning and heat mapping bring a new level of efficiency and precision to floor flatness analysis—ensuring specifications are met, construction components are more plumb, square and level, corrective work is avoided, and budgets are maintained.

Applications of Heat Maps Throughout the Project Lifecycle

Accurate floor flatness is critical to the success of any project—from design through long-term use. With 3D scanning and heat maps, teams gain precise, visual data that guides planning, construction, verification, and maintenance, minimizing costly surprises and ensuring lasting performance.

Before Construction

Before construction begins, 3D scanning and heat maps allow architects and engineers to visualize foundation variations, set tolerance benchmarks, and plan material use with confidence. In retrofits or adaptive reuse scenarios, such as converting office space into a laboratory, heat maps reveal hidden issues early, enabling targeted remediation before new systems are installed.

During Construction

3D scanning and heat maps provide real-time quality control, especially during concrete slab placements, by highlighting high and low points prior to the next phase of construction. They are also critical when installing flooring systems such as marble, polished concrete, or large-format tile, where ultra-flat surfaces are essential for both aesthetics and structural integrity. By validating flatness before finishes are in place, heat maps safeguard quality and ensure long-term performance.

Post-Construction Verification

In facilities—such as warehouses, hospitals, laboratories, cleanrooms, and advanced manufacturing plants— heat maps confirm compliance with strict flatness tolerances. Since even small irregularities can impact safety, cause premature wear on machinery, or disrupt operations, providing clear visuals of elevation changes provides peace of mind for owners and operators. Such confirmation of floor flatness helps ensure these spaces meet the demanding equipment operating specifications.

Long-Term Operations & Maintenance

For owners, ongoing scans support predictive maintenance by detecting subtle changes in floor flatness over time, revealing wear patterns and signaling when renovations may be needed. In facilities where floors endure heavy, repeated traffic, such as forklifts in warehouses or pallet jacks in distribution centers, heat maps and frequent scans are especially valuable, as early detection enables targeted resurfacing or repair before problems escalate into costly structural issues. In commercial real estate, heat maps can also play a role in lease disputes, serving as documented evidence of floor conditions at turnover and helping resolve conflicts between tenants and property owners.

Transforming Flatness into Performance

Heat maps take the complexity out of floor flatness verification by turning millions of precise data points into a clear, color-coded view of surface conditions. This makes it easy for practitioners to quickly pinpoint high and low spots, prioritize corrective action, and keep work moving forward.

Because the data is captured through survey-grade 3D laser scanning, elevation measurements are accurate to within millimeters. This level of detail removes guesswork, minimizes the chance of costly errors, and helps teams avoid schedule setbacks and change orders. Moreover, by quickly identifying problem areas, teams can adjust while it’s still cost-effective to do so. In fact, early detection can prevent up to $450,000 in unexpected remediation costs for a typical 50,000-square-foot building, with actions like cut-and-fill analysis streamlining the process and mitigating costs.

Beyond cost and efficiency, heat maps play a vital role in risk reduction. Floors that meet precise flatness tolerances not only support equipment performance and finish durability, but also reduce the risk of trip hazards and long-term structural issues. By helping surveying professionals leverage 3D scanning data for proactive quality control, heat maps lead to smarter, faster, and safer construction.

Project Spotlight: Gymnasium Floor Flatness

To support our client’s needs to achieve precise floor flatness to prepare for the installation of a new gymnasium and its specialized equipment, DGT utilized the NavVis VLX and Faro 3D laser scanners, along with a total station, to capture existing conditions and generate a point cloud. From this data, heat maps were created to pinpoint high and low areas requiring correction.

Using these maps, the client identified and addressed compromised areas, while DGT assisted by laying out sections to be scarified or filled. This targeted remediation allowed the construction team to deliver the specified flatness, ensuring the floor was ready for safe and reliable equipment installation.

Raising the Bar for Flatness Verification

Heat maps powered by 3D scanning are transforming the way the construction industry approaches floor flatness verification. By combining millimeter-level accuracy with clear, visual representation, they allow project teams to detect and correct issues earlier than ever before. This early detection not only saves time and reduces costs, but also helps ensure that finished floors meet the highest performance and safety standards.

In a field where accuracy powers performance, having the right data at the right time can make the difference between a smooth handoff and costly rework. With decades of surveying experience, DGT Associates delivers precise, reliable 3D scanning and floor flatness heat maps that keep projects on track, on budget, and built correctly.

To learn more about how DGT can support your next project, check out our 3D scanning and surveying services.